Telefon

:

+49 (0) 33 61 | 37 46 42

Fax

:

+49 (0) 33 61 | 37 52 12

E-Mail:

brau-konzept@t-online.de

Brau Konzept GmbH

Berliner Straße 19

15517 Fürstenwalde

The inexpensive microbrewery/ small brewery

with the high quality standard - after proven

handicraft and building tradition.

We provide ready for occupancy microbrewery

plants for you with an annual output from 500 to

5000 hl - when desired also with a higher annual

output.

The offer in the overview:

•

Consultation

•

Planning

•

Calculation of production costs

•

Licensing procedure

•

Training

•

Recipes

•

Raw material procurement

•

Accessories

•

Service

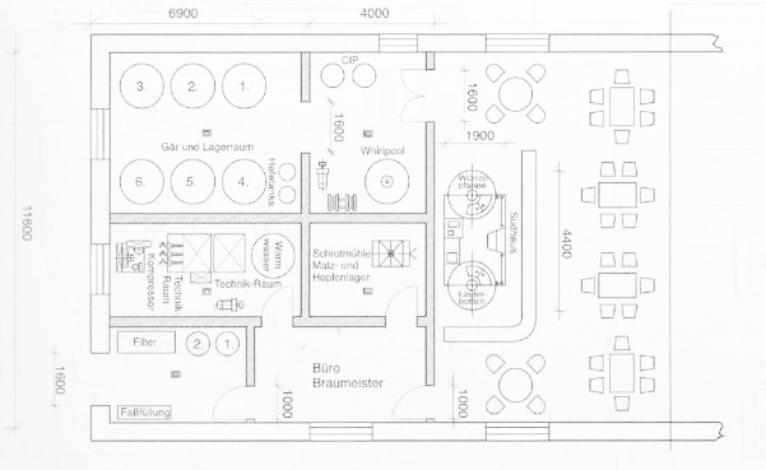

20hl - Mash House

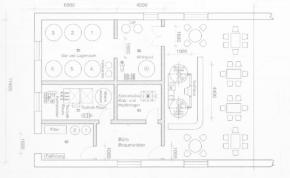

Typical restaurant brewery/ microbrewery with

1000 hl annual output (5hl - Mash House)

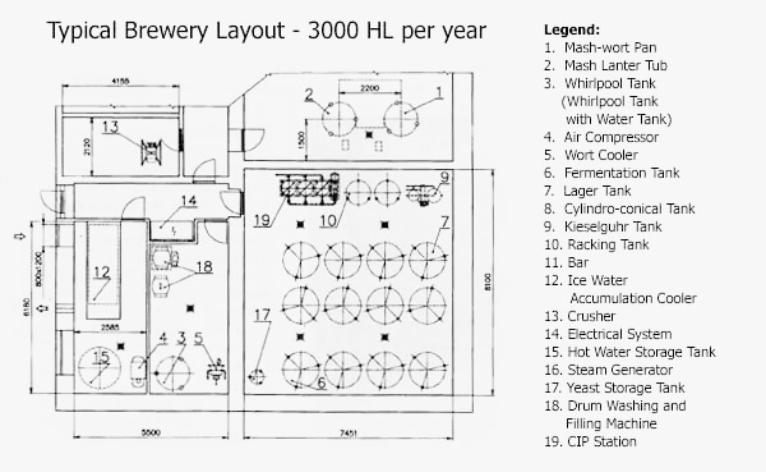

Typical restaurant brewery/ microbrewery with

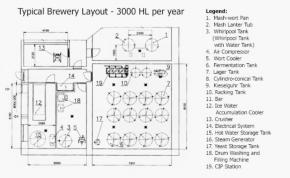

3000 hl annual output

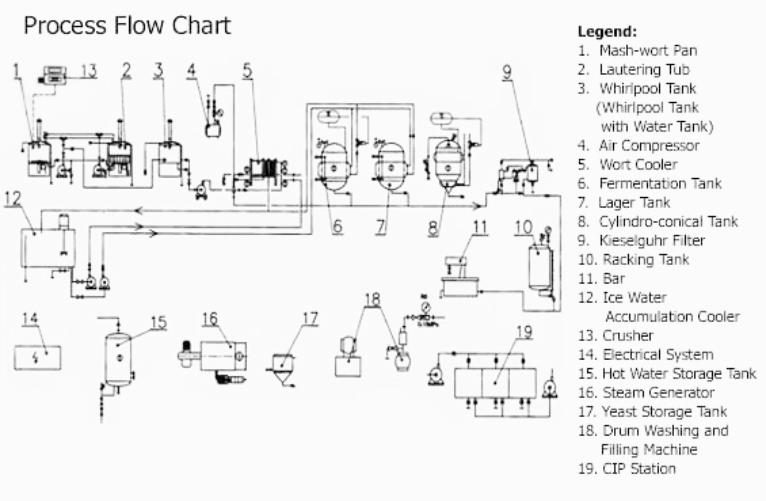

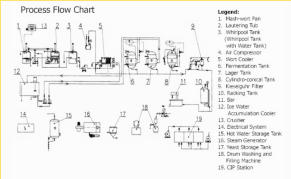

Microbrewery - Process Flow Chart

Microbrewery Description

The microbrewery described here can be installed for the required capacity ranging from 1.000 up to

5.000 hl beer/ year.

The end price for the standard equipment includes all

material, transport and the installation.

The size of delivery depends on your own wishes and

on the separate units and the technical and

technological requirements for the separate units.

The whole construction of the microbrewery is

conceived according to the most up-to-date science of

brewing.

The microbrewery is userfriendly, does not need much

maintenance and as a consequence can be run at

reasonable prices.

Beer of perfect quality can be produced with this mini-

brewery. You have the choice from a variety of beers.

The malt needed for brewing is in general to be

delivered in sacks and is grinded down to ground malt in

a grist mill.

The mash house consists of a mash and lauter tun and

a mash and wort pan connected to each other and to

the whirlpool. The to tubs and the whirlpool are of high

grade steel with traditional copper domes. An operating

platform gives access to all three tubs.

The fermentation and storage tanks of the microbrwery

are to be found in the tank room. The tanks are

cylindrical in form with a cone at the bottom and are

supplied with a cooling jacket. After fermentation and

storage the beer is pumped into the dispenser tank from

where it can be poured either filtered or unfiltered.

You also have the choice of beeing able to fill the beer

into barrels or bottles.

The yeast needed for the fermentation is kept in special

tubs which are cooled.

For the energy supply electricity or steam is required. A

rapid steam generator produces the steam which is

necessary to boil the wort. This process can also be

achieved using an electrical heating system.

Tap water is used for beer production and for cooling.

The warm water, which is gained from the cooling can

be used in the next brew or to clean the installation.

The cooling machine produces ice water which

permanently circulates within the cooling system, to

refrigerate the fermentation and storage tanks. In this

case the fermentation room does not require its own

cooling system.

Microbrewery - 5hl - Mash House

Microbrewery - Bottle Filler - CKT

Microbrewery - Tank Room

Microbrewery - Refrigeration Plant

Product & Services

![Schließen [x]](index_htm_files/close.png)